National Institute of Technology Rourkela researchers, led by Prof. Angana Sarkar, Associate Professor, Department of Biotechnology & Medical Engineering, have developed a process to remove pharmaceutical pollutants from wastewater.

The two-stage process combines adsorption and biodegradation to tackle a wide range of pharmaceutical compounds, including antibiotics, non-steroidal anti-inflammatory drugs (NSIDs), and synthetic dyes.

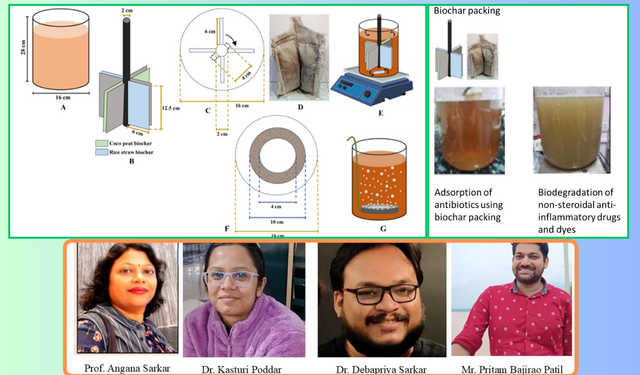

The study was published in the prestigious Journal of Water Process Engineering. The paper has been coauthored by Prof. Angana Sarkar, along with her research team Dr. Kasturi Poddar, Dr. Debapriya Sarkar, (Research graduates) and Mr. Pritam Bajirao Patil (Research scholar).

Pharmaceutically active compounds (PhACs) have become contaminants of emerging concern due to their bioaccumulation and biomagnification through the food chain, posing significant risks to humans and aquatic organisms even at trace concentrations. These endocrine-disrupting chemicals interfere with hormonal systems, causing acute health issues.These pollutants enter water systems through domestic sewage, hospital waste, pharmaceutical industries, and livestock farming. For instance, a study found that the Musi River, Telangana contained over 5 milligram per liter (mg/L) of ciprofloxacin, an antibiotic, due to nearby drug manufacturing industry.Adverse effects have been observed in lower trophic levels, such as fish, mussels, and birds, with incidents like fish mortality and declining eagle and vulture populations in the Indian subcontinent.Additionally, these pollutants pose serious health risk to humans, including kidney and liver damage, hypertension, and developmental issues. Antibiotics in wastewater are particularly concerning, as a large amount is excreted unchanged, contributing to the rise of antibiotic-resistant bacteria.Conventional wastewater treatment methods struggle to remove these contaminants, allowing them to persist in rivers, lakes, and groundwater.

To address these challenges, the NIT Rourkela research team developed an integrated treatment process that effectively removes pharmaceutical pollutants through a two-stage approach. In the first stage, the antibiotics are captured using biochar adsorbents derived from roasted coco peat and rice straw. This step significantly reduces antibiotic contamination before the biological treatment phase.The second stage employs a specialized bacterial group, including Klebsiella and Pseudomonasstrains, to break down residual pharmaceutical compounds such as diclofenac, paracetamol, and synthetic dyes.

When tested on synthetic wastewater containing a mix of NSAIDs, antibiotics, and pharmaceutical dyes, the system demonstrated excellent removal efficiencies. Biodegradation efficiency of pharmaceutical dyes and painkillers was more than 95 %. The biochar adsorption process also proved highly effective, removing over 99.5% of antibiotics from the water.

Speaking about the significance of the research, Prof. Angana Sarkar, Associate Professor, Department of Biotechnology & Medical Engineering, NIT Rourkela, said,“Our innovative integrated system efficiently removed various pharmaceutical pollutants, including antibiotics, NSIDs and dyes. The process is completely safe using biologically derived methods with no toxic intermediates. The process protects biodegrading bacteria, minimises toxic byproducts, and enhances the eco-friendly management of pharmaceutical contaminants. The treatment costs about Rs. 2.6 per liter and it can be further reduced by process optimisation and integrating this system as a tertiary step in existing treatments.”

The researchers suggest that this process is nontoxic, sustainable, and cost effective that can be scaled up in near future in collaboration with the pharmaceutical industries.

The system, demonstrated with model pharmaceutical compounds, can be applied to other molecules with similar structures. Further treatment through standard wastewater treatment eliminates the need for additional stages for bacteria and solid residue removal.

Future studies will focus on recovering and purifying adsorbed antibiotics from biochar, offering a valuable resource that could generate profit and reduce pharmaceutical manufacturing costs. This recovery could make medicines more affordable for underserved communities. Additionally, antibiotic-free biochar can be repurposed as fertiliser, ensuring a zero-waste process

This project was funded by Science and Engineering Research Board (Under IMPRINT-2: Impacting Research Innovation and Technology, Government of India Scheme) and research work was conducted in collaboration with Cadila Pharmaceutical Ltd., Ahmedabad, India.