Bhubaneswar: Preventive maintenance of rolling stock is a need and necessity of the hour. In this concept, the fault is detected before the actual occurrence of failure. An alarm is generated by this system which is about to fail. Necessary action is taken immediately before the actual failure. This ensures safe running of trains. The East Coast Railway (ECoR) has installed “Hot Axle Box Detection System” at Belsonda, Boinda & Brundamal Stations over Sambalpur Division.

This is a system based on sensors which gathers information on Rolling Stock conditions like Bearing condition, and Axle Temperature etc., of the trains. In this system, the proximity sensors are installed on the wayside stations detects the presence of incoming trains. The temperature sensors measure the temperature of axles. It compares the temperature record of each Axle with the reference temperature which is set in the system. If the measured temperature exceeds the set temperature, system generates alarm to the control office on real time basis. Based on it, the control may take the necessary action.

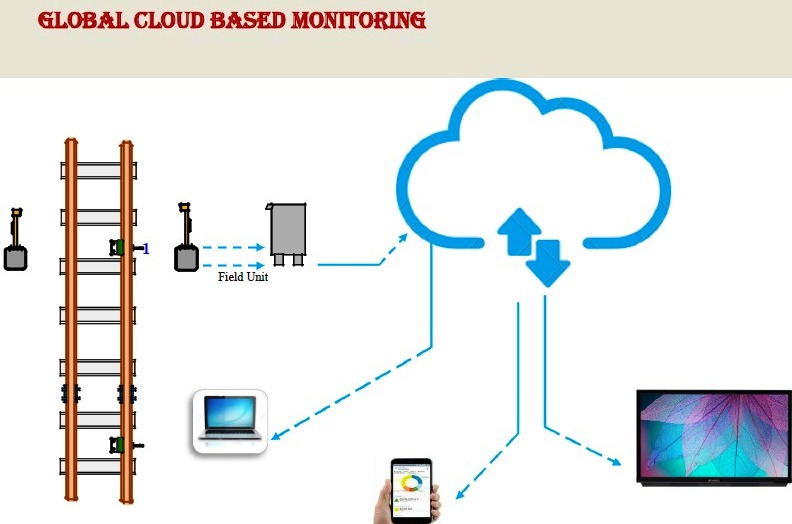

The main function of the system is to receive the data from sensor, send the data to the microcontroller unit, to web cloud server from the main server. This will show as a live data displayed at Control Room.

The data can be viewed and monitored through computer as well as through mobile. This System will generate ‘SMS’ as well as email alert and generate “Visual Alarm” in the main display screen.

This system will prevent any en route failure of rolling stock, which if happens, leads to disruption of traffic and loss of punctuality for passenger trains. BY this system, once a high temperature is detected, the particular wagon or coach will be detached at the nearest station.